Rebound Resilience

ASTM D7121 and ASTM D2632

Rebound Resilience Summary

This test method measures the percentage resilience of a rubber compound.

At ACE Products and Consulting, we use two rebound resilience test methods: ASTM D7121 and ASTM D2632. At ACE, we are committed to producing repeatable, accurate, and timely results so you can produce polymer products of the highest possible quality.

Rebound Resilience Testing

What is a resilience test?

Rebound resilience is the relationship or ratio between the returned energy and impact energy between a force, like a dropped hammer, and the sample specimen. Your material’s energetic response to an impact, typically delivered by a hammer, is measured, then analyzed depending on the objectives and quality control standards to establish its readiness for its end application.

When is knowing rebound resilience useful?

Rebound resilience tests are often used for research and development and quality control to ensure a product is meeting industry standards. They can also be useful for determining whether or not a material is the right choice for its intended application, or if a product is ready for its end use.

Resilience tests can be performed at a range of temperatures, above, below, and at application temperature, as well as at variable conditions of strain. Through repeated testing in a variety of strategic conditions, you can gain valuable knowledge about your material’s rebound resilience in a range of conditions, rather than at just one set point.

It is also important to test rebound resilience if you are deciding between multiple materials for an end application. No one material can be perfect in every way; it is important to know the resilience of your materials–along with its other properties–so you can make informed decisions about your product.

Resilience Test Details

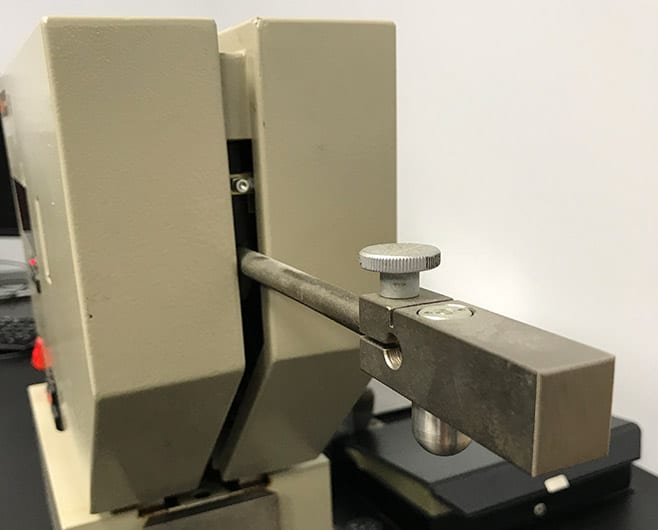

ASTM D7121 and ASTM 2632 are two rebound resilience tests that function similarly, but measure the resilience of your material in slightly different ways. The results from either of ACE’s resilience tests measure energetic ratios and, to an extent, material dampening properties, based on the extent to which a pendulum rebounds after impact with your sample.

The right test for you will depend on the type of material you are testing, and the overall goal of the analysis. ACE’s rubber testing experts can help design the right course of testing for your needs.

ASTM D7121

What is an ASTM D7121 test?

ASTM D7121 measures the percentage resilience of a rubber compound, where the percent rebound is inversely proportional to the hysteretic energy loss.

During ASTM D7121 testing, a pendulum hammer freely falls from a predetermined height to impact your material sample. The hammer is configured to impart a certain amount of energy. A portion of that energy is then returned by your sample to the rebound pendulum. This return of energy can then be measured by the extent of the pendulum hammer’s rebound.

The test allows ACE to describe the determination of resilience by the rebound device (pendulum) as a ratio between the returned and applied energy when a spherically terminated mass impacts your sample under specified conditions. This determination is expressed as a percentage resilience, or rebound resilience.

The results of this test–and the rebound resilience of the sample material–are greatly affected by the predetermined specific conditions, such as temperature, strain rate, and strain energy. ACE will perform repeated tests with your material sample under the same conditions to provide meaningful, repeatable, and reproducible data you can count on.

ASTM D2632

What is an ASTM D2632 test?

The ASTM D2632 test observes the impact resilience of solid rubber by measuring the vertical rebound of a dropped plunger of a prescribed mass and shape. Resilience is then determined as the ratio of rebound height to the drop height of the hammer. Once again, the resilience measurement is sensitive to changes in temperature and depth of the plunger’s penetration.

ASTM D2632 is used to develop and compare materials, but is not applicable to the testing of end-use performance in many cases. It is also not applicable to the testing of cellular rubbers or coated fabrics, but is appropriate for the testing of cellular rubbers or coated fabrics.

The most defining difference between ASTM D2632 and our other rebound resilience test, ASTM D7121, is that ASTM D2632 is a vertical test, while ASTM D7121 is a pendulum-style resilience test. Because of rebound resilience’s sensitivity to conditions, repeated, controlled testing with more than one method can offer a well-rounded understanding of its properties.

Resilience Test Results

Resilience test results provide valuable pieces of information to consider when developing a new material, improving an existing one, or maintaining quality control.

Once you know this information, consultants at ACE Products and Consulting can lend their expertise to the next steps in your research and development or quality control testing.

Contact us today to discuss a material testing plan that will take your products to the next level.

There's More!

ACE offers a full range of rubber and synthetic compound testing. If you are interested in a test method that is not shown, please contact us and we will do our best to accommodate your testing needs.