Differential Scanning Calorimetry

ASTM D7426 and ASTM D3418

Two of the most common test methods for DSC, ASTM D7426 and ASTM D3418, allow ACE’s expert technicians to observe glass transition temperatures, melting point, heat of fusion, and the effects of crystallization.

At ACE Products and Consulting, differential scanning rubber calorimetry is an excellent tool for anyone looking to dig deeper into their research and development or quality control projects.

ACE’s experts provide observations and analysis on the performance and properties of your material that ensure your product is the best it can be.

What is Differential Scanning Calorimetry, or DSC?

How does a differential scanning calorimeter work?

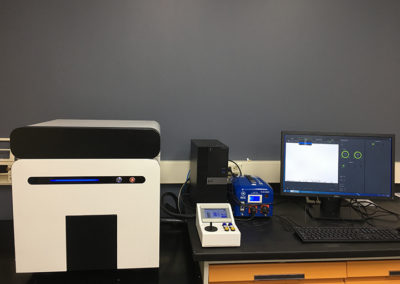

DSC testing begins with two components: a measurement chamber and a computer. Two pans are heated in the measurement chamber and your sample is placed in one pan for measurement. The other pan is left empty as a control. During the test, an ACE laboratory technician measures the sample’s temperature from below.

What is this test useful for?

DSC test methods are applicable to a range of end goals. In general, DSC will be useful if your material will encounter cold temperatures, encounter a wide variety of temperatures, or cool from a melt in its end use or during its production process.

Results with information on your material’s glass transition temperature, melting point, heat of fusion, and crystallization performance are all valuable for informing research and development projects.

With DSC, ACE can also study fusion, oxidation, and other chemical reactions, as well as purity and polymer curing. For these reasons, DSC is also an excellent choice for quality control testing and meeting industry standards.

At ACE, we pride ourselves on the repeatability of the test results we offer you. DSC testing delivers precise readings that are reliable.

DSC Test Method Details

Two common DSC test methods are ASTM D7426 and ASTM D3418. Between these two standard test methods, ACE can determine your sample’s glass transition temperature and melting point, as well as observe its heat of fusion and crystallization behaviors.

ASTM D7426

What is the ASTM D7426 test method?

ACE’s DSC procedure for determining glass transition temperatures is ASTM D7426.

A glass transition temperature is the temperature below which your material becomes brittle and glass-like. If your material drops below that determined glass transition temperature in its real-life application, its performance will suffer.

This makes ASTM D7426 an important test method for observing the performance of polymer materials that will be exposed to cold conditions during its manufacturing process or end use.

ASTM D3418

What is the ASTM D3418 test method?

ASTM D3418 uses DSC mainly to determine three factors: melting point, heat of fusion, and the effects of crystallization.

Melting Point

Data about melting is often collected through a simple melting point device. However, using the DSC to measure melting point instead provides you with more precise, accurate, and reproducible results.

DSC testing offers detailed insight into the melting properties of your material. For example, you will learn not only the onset of melting temperature, but also the peak temperature, or complete melting point.

Heat of Fusion

Heat of fusion is the amount of energy that is needed to melt a predetermined mass of your sample at its melting point temperature. By measuring the heat of fusion, ACE can provide valuable information about your sample’s properties under extended periods of hot conditions.

Crystallization

When a polymer material is about the glass transition temperature, its polymer chains have mobility. Measuring crystallization with DSC involves determining the temperature at which these chains have the energy needed to form ordered arrangements. In other words, at what temperature does this material crystallize?

With DSC testing, this can be observed when your material cools from melting. From there, we can gain insights on crystallization’s effects on various polymer properties, such as mechanical, thermal, and chemical.

Contact ACE Products and Consulting

ACE is proud to offer our clients high quality, repeatable test results and quick, responsive service with integrity. Our experient laboratory technicians work hard in our ISO/IEC 17025 accredited laboratory to provide you with useful, thorough, and precise results.

When you work with ACE, you gain a partner you can trust, ready to meet challenges head-on and take your product to a new level of excellence.

Does DSC testing sound like it would benefit your product? Contact us today to get started.

Differential Scanning Calorimetry (DSC)

Differential scanning calorimetry, or DSC, is a thermoanalytical technique. It is used in determining the difference in the amount of heat required to increase the temperature of a sample. The reference is measured as a function of temperature.

FTIR

The Fourier Transform Infrared (FTIR) is commonly used to determine the polymer type present in a compound.

HPLC

High Performance Liquid Chromatography (HPLC) is used to detect a wide range of analytes in solution either qualitatively or quantitatively.

ICP-MS

The ICP-MS California Proposition 65 provides routine ultratrace level analysis to perform analyses at the parts per trillion level and lower.

Scanning Electron Microscope (SEM)

The SEM-MMT X-Factor 150 Scanning Electron Microscope allows qualitative, quantatative, and thickness analysis on materials. The high-resolution imaging of samples provides sample observation with a greater focus on a sample’s depth and structure.

Thermogravimetric Analysis (TGA)

This test method is intended for use in quality control, material screening, and related problem-solving. It is useful when a compositional analysis, or comparison to a known material, is desired.

X-Ray Fluorescene (XRF)

The XRF (X-Ray Fluorescence) analyzer is the most common tool used for RoHS compliance testing.